虎'TIGER' MOTORCYCLE

YEAR

IN PROGRESS 2022

MATERIAL

STEEL, STAINLESS STEEL, ALUMINUM & MOTORCYCLE COMPONENTS

Building on my previous e-bike project, the goal of this project is to create a café racer inspired by classic motorcycle culture and the free-ride ideology within 13 weeks. As someone who doesn’t know how to ride a motorcycle and has no prior knowledge of motorcycle mechanics, I see this as a fun challenge—an opportunity to learn about motorcycles as I build one.

Since 2022 is the Year of the Tiger—a strong, powerful, and aggressive animal—I drew inspiration from its characteristics to shape this motorcycle, using it as a reflection of my identity.

Test riding my motorcycle for the first time (riding any motorcycle for the first time) and putting the basic motorcycle theories I learned from YouTube to the test in the real world.

Also, the brakes weren’t set up yet.......

WEEK 0 - WEEK 1

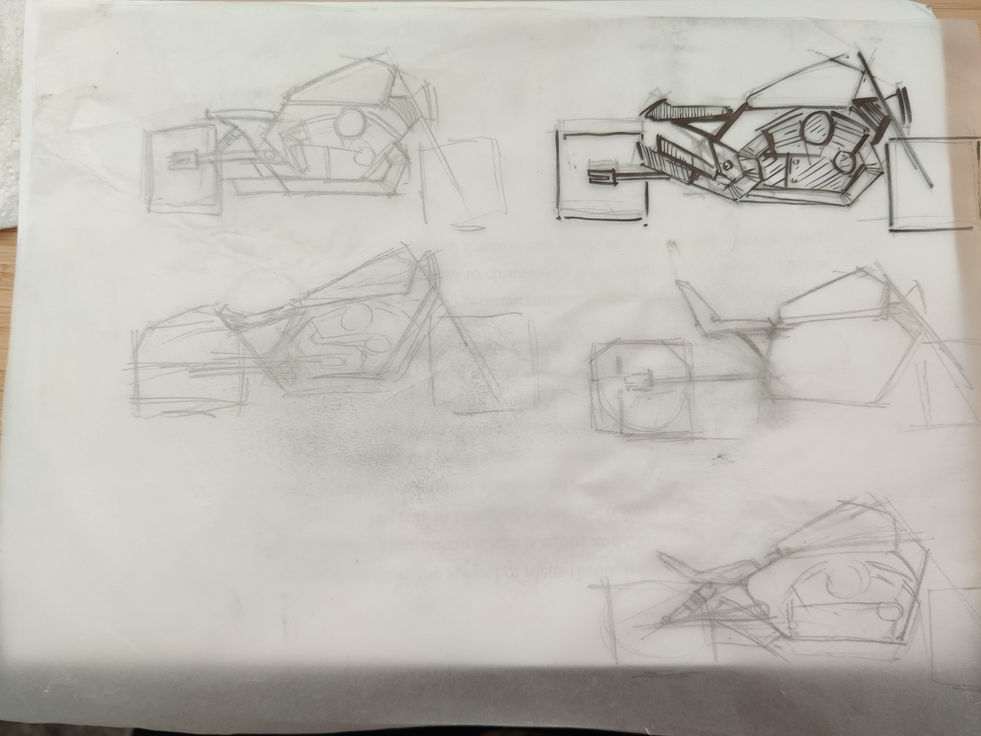

Before the beginning of the semester, I have started my projects with research and modeling to understand the geometry of a motorcycle frame more. With no knowledge about motorcycles when jumping into this project, everything seems new and exciting. I started planning the frame and the jig I need to weld this frame and began my operations for the project.

WEEK 2

For week 2, I started my journey by visiting Madhouse Motors and having a chat with J. The chat with J made me develop a better understanding of motorcycles and a better direction on what I should do.

Started my process of building a custom motorcycle jig with parts from 'Chop Source' @DMW

I started doing more sketches and decided on using a Harley Davison Sportster 883 V Twins engine. To form a better understanding on the frame geometry and the mounting points for the engine, I bought an old frame and did measurements using Solidworks.

WEEK 3

With a better understanding of the geometry, I modified my design to a more bobber-style design and started the process of sourcing materials for the main frame and preparing them.

WEEK 4

Let the welding process begin! As you may tell, my welds have improved since the e-bike project. On one hand, bike tubing is much thinner and harder to weld; on the other hand, I have been practicing. XD XD

The process was a rollercoaster. The first frame I made was too small for the engine. At that point, I learned that Harley engines went through a major transition from rigid mount to rubber mount. I also realized that I shouldn’t have taken too much reference from the OEM frame, as OEM frames are designed for precise factory fitment, which isn’t very friendly for a project like this. With some brain work and calculations, I remade a frame that fits the engine.

Now it's time to get a feel for being a biker! Maybe some monkey bar? Modeling by: Scott.

WEEK 5-6

Started the process of fabricating motor mounts. Rubber mounts weren’t the best choice for a custom motorcycle build, but I eventually figured out a proper way to mount the engine onto the frame.

WEEK 8-10

As the final critique for the class approaches, the motorcycle is still missing many parts, and the frame needs to be powder-coated. After week six, I spent a lot of time shopping for parts and making final touches on the frame.

WEEK 11-13

The frame is back from powder coating, and the wiring process has begun. Ideally, it should be a plug-and-play setup, but it turned out to be far more complicated than I could have ever imagined.

A big thanks to Josh, Scott, and Kyle from DMW for helping me out—sharing their motorcycle expertise and troubleshooting the electronic side of a Harley engine.

Tried to start the motorcycle but failed. I discovered the reason a year later when I returned to Boston to work on the bike—Harley's security system was preventing it from staying running, and a hard reset was all it needed.

Even though the motorcycle still needs quite a bit of work to run properly, it was disappointing that I couldn’t show my project running during my final critique for the class. Especially now, as I’m writing this, knowing how easily the problem could have been solved.

A YEAR LATER......

After graduation, this project kept coming back to my mind, reminding me that it wasn’t finished yet. After a year, I finally planned a trip back to Boston to try finishing it up.

During my one-week 'vacation'—with help from DMW—not only did I get the motorcycle to stay running, but it also ran... just without brakes!

In the video below, you can see Josh starting the motorcycle. As you can also see, there are a lot of wires that still need to be sorted out, which means this project is still far from being completely finished. :(

Since I don’t know how to ride a motorcycle or have a motorcycle license (still to this day), nobody trusted me to test ride a brakeless motorcycle—especially one built by someone like me.

So, big thanks to the brave Josh for taking on the test ride!

And here are some cute pictures of me with my project.

ANOTHER YEAR LATER......

Picked up the motorcycle from Boston and brought it back to NJ. There’s still much work to do...

Thank you for taking the time to check out my entire process on this motorcycle.

In the end, I want to once again express my deepest appreciation to Scott, Kyle, and Josh @DeathMetalWerks—without them, none of this would have been possible.

A massive thank you to the countless people I met on this journey who shared their knowledge and experience with me and helped me solve my amateur problems.